I.Material Composition and Defect Analysis Service

The company possesses metallurgical microscopes, Scanning Electron Microscopes (SEM with EDS), and a team of technical experts. We provide comprehensive analysis including:

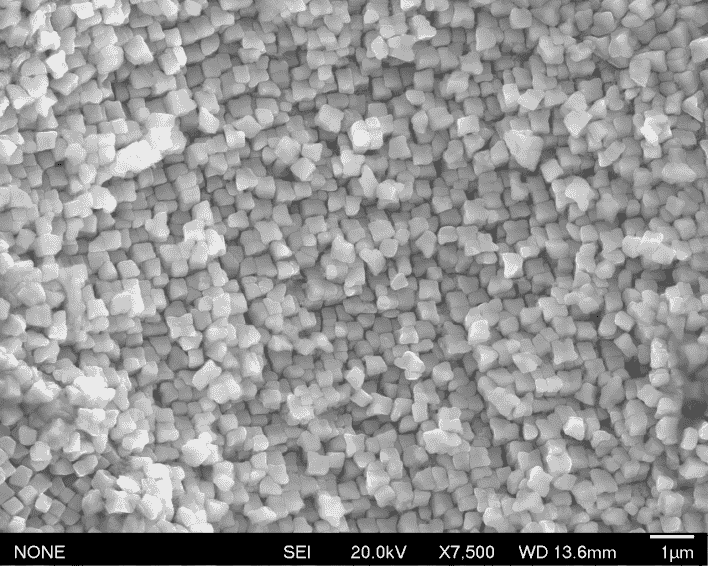

● Alloy grain size

● Phase composition

● Distribution of precipitates

This analysis supports customers in optimizing heat treatment processes.

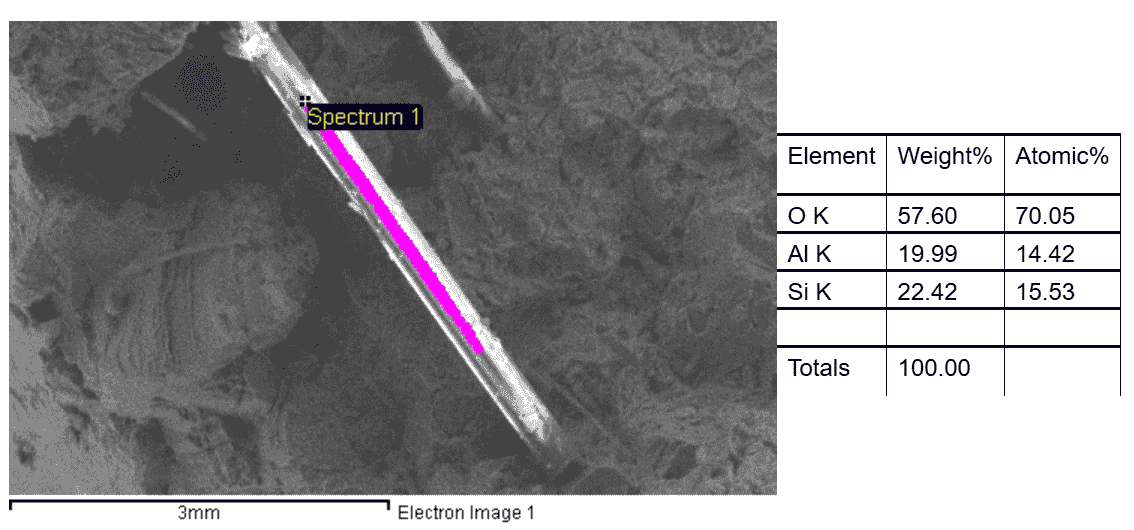

We also conduct casting defect analysis (e.g.,porosity, slag inclusions) to prevent component failure caused by material defects or process deviations.

Figure 5 SEM Observation of Strengthening Phases Figure 6 Inclusion Analysis via SEM+EDS

II.Customized Material R&D and Supply

The company consistently adheres to the development philosophy of "Open Innovation, Win-Win Cooperation," maintaining close industry-university-research partnerships with leading domestic and international institutions. Our R&D team, composed of PhDs and Masters specializing in metallic materials, boasts 13 years of specialization in superalloys, forming a fully-equipped R&D and production unit covering material smelting, casting, and analytical testing. We possess core technologies for producing superalloys, wires, and powders. Leveraging our integrated superalloy digital twin platform--featuring material computation, performance simulation, and process modeling--we rapidly validate new material compositions and process routes in dedicated software. This enables the customized development and optimizationg of superalloy raw materials tailored to clients' specific production process requirements, enhancing their product performance and yield rates.